Menu

Designed to Perform.

Built to Last.

CERAMIC

Evlos delivers precision-driven automation and machine vision solutions for ceramic substrate manufacturing, where dimensional accuracy and surface integrity are critical. Our systems automate handling, alignment, and inspection processes to ensure consistency across high-volume production environments.

Through advanced vision inspection, we detect micro-defects, surface cracks, and dimensional deviations early in the process. By integrating automation from material handling to final inspection, we help manufacturers improve yield, reduce manual dependency, and maintain strict quality standards.

CONSTRUCTION

For the construction sector, Evlos engineers automation systems that improve throughput, accuracy, and repeatability in material processing and inspection. Our solutions are designed to handle heavy-duty components while maintaining precise quality control.

Using machine vision, we automate dimensional checks, surface inspections, and defect detection across construction-related manufacturing processes. This enables our customers to reduce rework, improve safety, and maintain consistent output across large-scale operations.

DIE CASTING

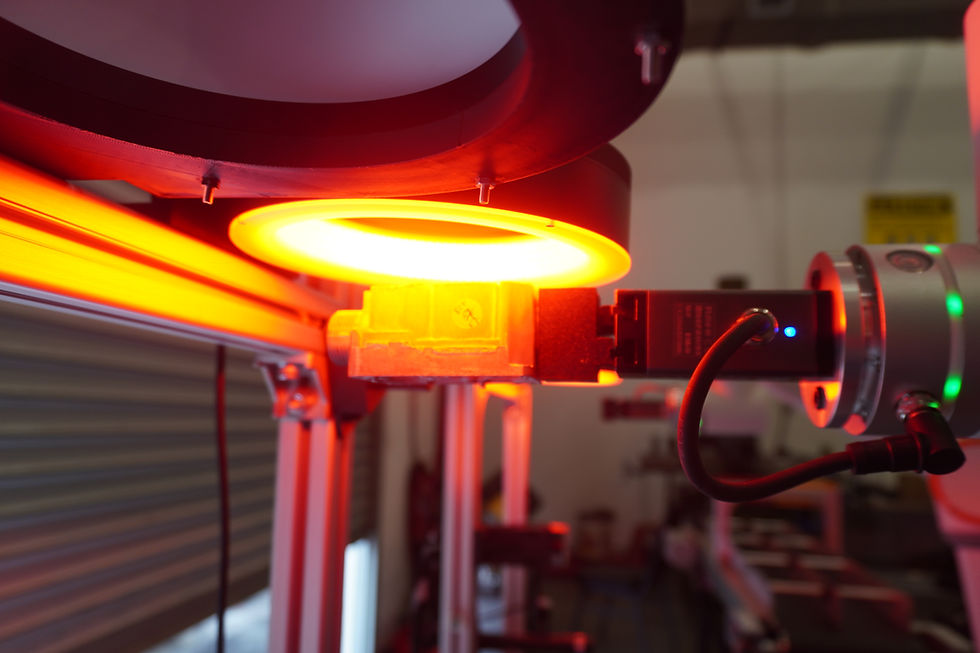

Evlos supports die casting manufacturers with end-to-end automation solutions that address both productivity and quality challenges. From automated part handling to post-casting inspection, our systems are built to perform reliably in high-temperature, high-cycle environments.

Our machine vision solutions inspect cast components for surface defects, dimensional accuracy, and structural inconsistencies. By integrating inspection directly into the production line, we help customers minimize scrap, shorten cycle times, and achieve stable, repeatable quality.

ELECTRONIC

In the electronics industry, Evlos delivers high-precision automation and vision inspection systems designed for delicate components and tight tolerances. Our solutions automate assembly, alignment, and inspection processes across a wide range of electronic manufacturing applications.

With AI-powered machine vision, we inspect solder joints, component placement, surface defects, and dimensional accuracy at production speed. This ensures higher yields, reduced manual inspection, and consistent quality across high-mix, high-volume electronics environments.

FOOD & BEVERAGE

Evlos provides automation and machine vision solutions tailored for food and beverage production, where hygiene, accuracy, and compliance are essential. We automate processes such as labeling, packaging, sorting, and inspection based on each customer’s specific production requirements.

Our vision systems inspect labels, seals, product integrity, and contamination in real time, ensuring only compliant products reach the market. By integrating automation throughout the line, we help food and beverage producers improve efficiency while maintaining strict quality and safety standards.

GLOVES

For glove manufacturers, Evlos designs automation systems that improve consistency, speed, and quality across production and inspection stages. Our solutions automate handling, counting, and inspection to support high-output manufacturing lines.

Using machine vision, we inspect gloves for defects such as holes, tears, thickness variations, and surface imperfections. This allows manufacturers to reduce manual inspection, improve yield, and maintain consistent product quality at scale.

MANUFACTURING

Evlos delivers flexible automation and vision inspection solutions across general manufacturing environments. Our systems are designed to adapt to varying product types, production volumes, and quality requirements.

By combining automation with machine vision, we enable manufacturers to automate assembly, inspection, and material handling while maintaining real-time quality control. This results in improved efficiency, reduced labor reliance, and more predictable production outcomes.

PACKAGING

In packaging operations, Evlos automates processes such as case packing, labeling, sealing, and inspection to ensure speed and accuracy. Our systems are built to integrate seamlessly into existing production lines with minimal disruption.

Our machine vision solutions verify label placement, barcode accuracy, seal integrity, and package completeness. This helps customers reduce rejects, maintain compliance, and deliver consistent packaging quality at high throughput.

PLASTICS

Evlos supports plastics manufacturers with automation and inspection systems designed for high-speed, high-volume production. Our solutions automate part handling, trimming, and inspection to improve consistency and reduce manual intervention.

Through machine vision inspection, we detect surface defects, dimensional inconsistencies, and molding imperfections in real time. By integrating inspection directly into production, we help plastics manufacturers improve yield, reduce waste, and maintain consistent product quality.